Buy a still from the manufacturer from Germany

More distilleries from the manufacturer can be found at destillen.com

Waterbath liquor distillery

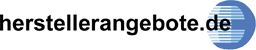

DESTILLIERMEISTER JUMBO-Premium WD42

Distillery with 42 liters of still volume, columns and dephlegmator

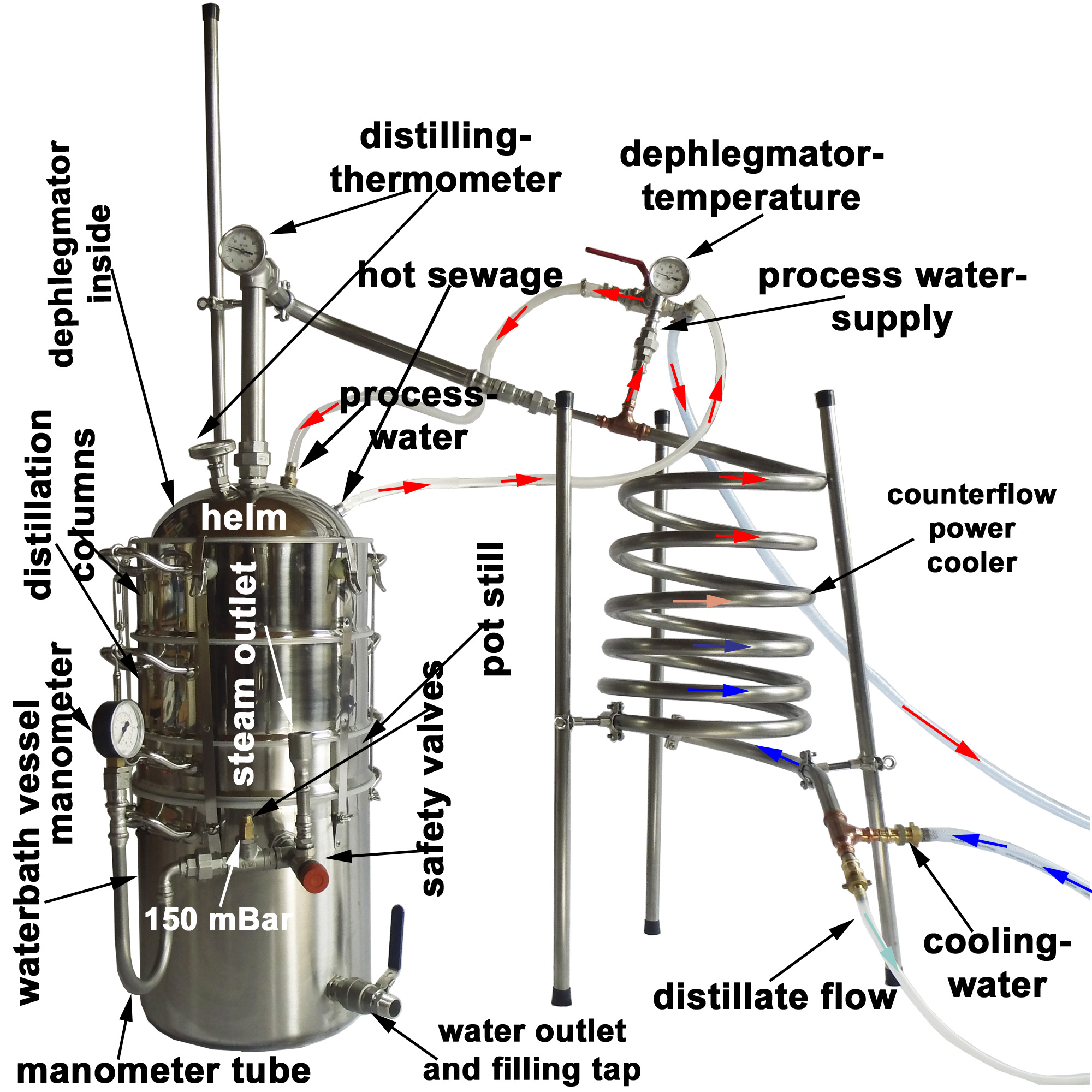

Essential Oils and Hydrolates

Legal in most contries

Buying a distillery means you should be clear about its main area of use: distilling essential oils or distilling schnapps. Distillery should be optimized for the purpose.

In a direct distillation of the essential oils contained in flowers and leaves many of the aromas would be destroyed because the evaporation temperatures of these oils are well above the evaporation point of the water. As aroma-conserving method, therefore, the steam distillation is used. For this purpose, steam with sufficient dynamics is generated, which flows through the plant material contained in the plant basket. In the process, the oils dissolve out of the plants, attach themselves to the water molecules and are hauled out piggyback. In the cooler, the Hydrolatdampf is cooled quickly. In the sampling jar, the water-insoluble oils settle on the hydrosolate (lighter oil) or on the base (heavier oil) depending on the type. With the help of an oil separator, the oils are easily separated from the hydrolate. But superheated steam can destroy many heat-sensitive ethereal aromas. Therefore, it must be ensured by suitable choice of the device parameters that overheating is excluded as far as possible. This can be achieved by minimizing flow losses at the bottom of the plant basket as well as by minimizing the pressure of the boiler by avoiding pressure losses due to the reduction of the cross section during the transition from the steam pipe to the cooler.

The DESTILLIERMEISTER model series E-XXXX Premium take account of this fact. Special basket bottoms with high permeability and precondensation of the hydrolate vapor enabled the optimization target to be achieved. The boiler pressure could be reduced from over 1000 Pascal to less than 10 Pascal, so that a steam overheating is practically impossible.

Of these, our top model is the DESTILLIERMEISTER JUMBO E7448 Premium with a maximum capacity of 48 liters of plants. In the premium models, the temperature is now measured at the point where they are interested, namely directly in the plant room.

Our top classics up to 65 liters to destillate the schnapps

DESTILLIERMEISTER JUMBO-Premium-Professional D50-Plus / D70-Plus

50 / 65 liter two-column still, dephlegmator and 2-way high-performance cooling

The DESTILLIERMEISTER JUMBO Premium Professional D70-Plus is the larger of 2 top models of the DESTILLIERMEISTER series. In the new versions, the countercurrent high-performance coolers are now set up separately. This significantly simplifies the design and handling. For reloading the boiler, the coolers no longer have to be moved. In terms of price, this distillation plant is still located in the hobby sector, but already has all the prerequisites for the professional production of noble distillates for small distillers. The high-end small distilleries, which are just as well suited for the production of high-quality aromatic fruit brandies as for the distilled alcohol from pure fruit pomace or from starchy products such as grain and potatoes, this 65 liter plant is at a top price of less than € 3000, - still well below the starting price of comparable investments in the professional sector, whose acquisition costs start in the five-digit range. The DESTILLIERMEISTER JUMBO Premium Professional is therefore a real alternative for small burners who want to avoid the high investment costs of a professional plant in the highly competitive alcohol market.

The system is operated in different modes. The realization of cooling and process water supply for the Dephlegmator via separate cooling paths for the pre- / after-run on the one hand and the middle run (Edelbrand) on the other. This avoids the risk that the inferior distillation fractions will not mix with the good brandy. In the present plant, both rectifier column and rectifier removal / reflux ratio control apparatus employ a controllable dephlegmator / flavor in the stainless steel helmet. The advantage over a pure column system, which has rather static parameters, is the controllability of flow and return, which makes the firing process more dynamic. Each distiller can determine the optimum operating conditions for his plant.

Only basic recommendations for the operation are given here. For pre- and post-run separation, settings adjusted to the respective task can be made. For fans of classic potstill distillations, the dephlegmator can also be easily turned off. The actual dephlegmator operationis generally required for the double distilling process for the fine distillate, because only the separation of pre-and post-run. For the crude destillate the dephlegmator can either remain switched off or be operated hot over the entire course, so that even here a higher alcohol concentration is achieved in the distillate.

Stainless steel - XXL format stills with columns, dephlegmator and high performance cooler

This type of distillery is particularly thick-walled and made of high-quality stainless steel. It has a volume of up to 60 liters together with the expansion pots. For better heat distribution, the bottom consists of a 3-layer capsule bottom, which is also capable of induction. This will offer a professional distillery of variable size. The expansion pots can be used as burn pot extension, as a flavor basket for fruit spirit production, as a plant basket for the distillation of essential oils by steam-to-tow distillation or as booster columns for liquor burning. Distilleries are offered with one or two amplifier columns. When using the 50 distillery as a distiller, one or two columns can be used. In addition, the helmet also fits on the fuel bladder, if the burner is to be operated as a pure potstill burner. The used countercurrent cooler / heat exchanger is designed as a spiral and has an extremely low cooling water consumption due to its length of more than 3 m with high cooling capacity. These burners are initially offered with 38 liter and 50 liter focal volume and in different versions. In the following two exemplary distillation plants of the upper category. Both are available with and without gas cooker.

DESTILLIERMEISTER JUMBO-PremiumD38 Plus

38 liters of distillery, helmet with dephlegmator, 1 column, distillation still with drain tap and 5 m separate high - performance countercurrent cooler

DESTILLIERMEISTER JUMBO Premium-D50 Plus

50 liters of distillery, helmet with dephlegmator, 2 columns, distilling kettle with drainage tap and 6 m long separately installed high - performance countercurrent cooler

ARD TV Film

My father-in-law, the smellfungus

ARD evening program from Friday the 11th Dec. 2015

Pictures from the filming of Tivoli Film Produktion GmbH with our Destilliermeister