Water bath distillery

Water bath for small distilleries – of course a stainless steel distiller

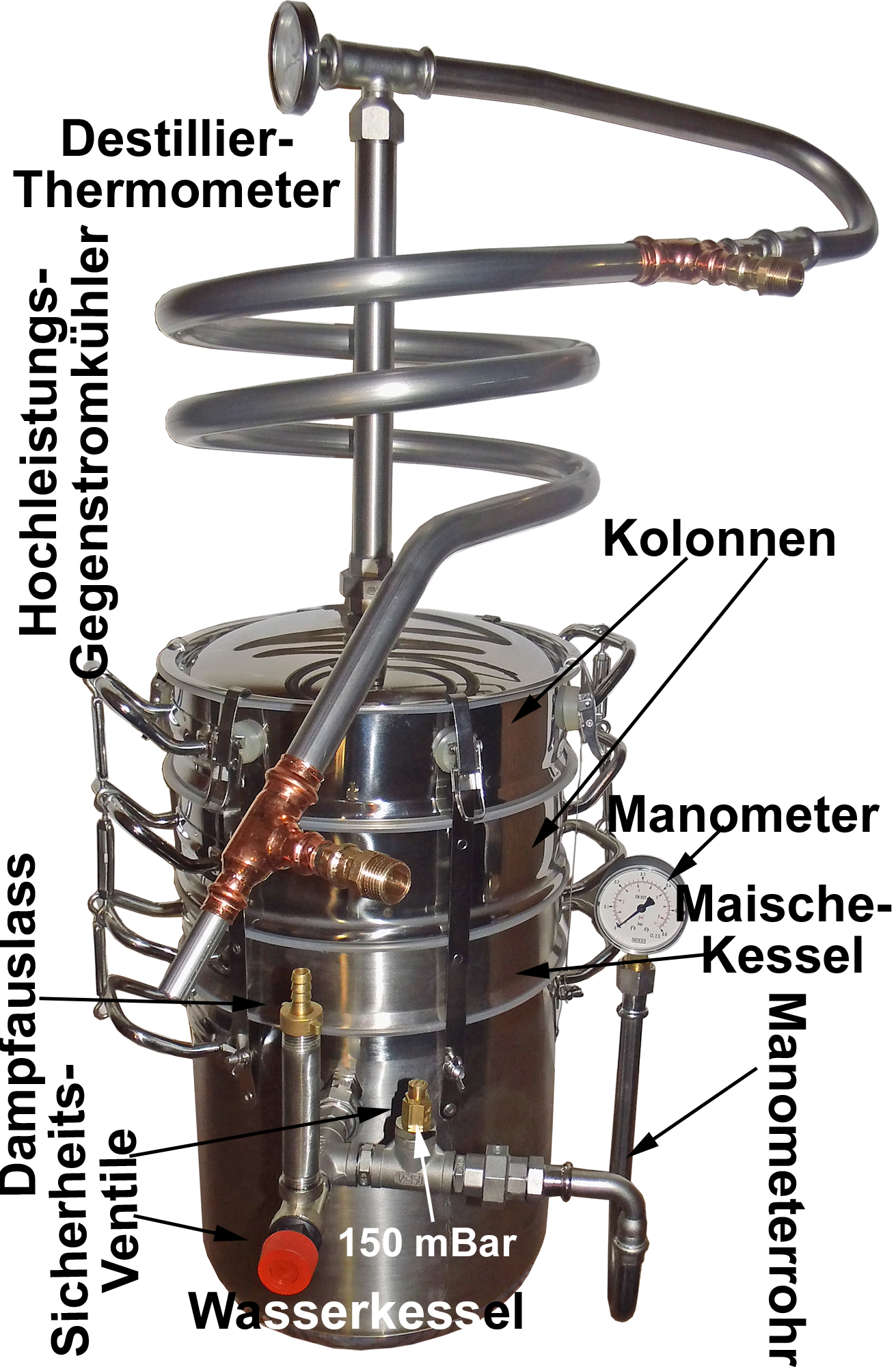

A new type of distillery for fans of experimental distilling. Burning mash, especially fruit mash with residual starch, is now a thing of the past. Distilling schnapps, especially in fruit distilleries, can now also be done on a small scale without burning the mash using a pressure water bath distillery.

2 Column:

- approx. 15 litres burning volume.

-

approx. 23 litres burning volume.

Special feature

These pressure water bath distillers are operated with a maximum water bath pressure of 150 mBar. The temperature of the water bath is then around 104 °C, so that the mash can be easily heated to the boiling point of water. In practice, a lower pressure would be used to ensure that the distillation proceeds slowly and that the components separate smoothly. For safety reasons, an overpressure valve opens between 100 and 150 mBar, limiting the temperature of the water bath to approximately 106 °C.

GPSR notes and manufacturer's information:

Information about copper stills can be found in the respective articles at the end of the article descriptions. The following information applies to all our stainless steel distillation devices Verdana,Geneva,sans-serif‘>The following information applies to all our stainless steel distillation devices

Danger warning: When used properly, our stainless steel distillers do not pose any particular danger. For water bath distillers, it is particularly important that the valves open when the pressure is too high. Therefore, the drain valves must remain unobstructed during operation and work in their vicinity must be avoided. As these distillers are for commercial use only, distillers should have experience in working with these devices.

All our devices are designed so that high pressures cannot build up. However, you should be aware that all parts become hot during distillation. We therefore strongly recommend wearing protective gloves and safety goggles during distillation, refilling and dismantling.nbsp;When using gas stoves, only devices with a flame failure device may be used. In indoor areas, the gas appliances used must be approved for indoor use.

Please be careful and observe the downloadable operating instructions.

Manufacturer's address:

herstellerangebote.de - Zerbster Str. 15 - 39279 Leitzkau - Germany, Email address: support(ad)herstellerangebote.de