Construction of optimized stills since 2006

New series with 12-liter plant volume, including everything you need for distilling, collecting, and analyzing

You save approx. EUR 60 compared to purchasing the items individually

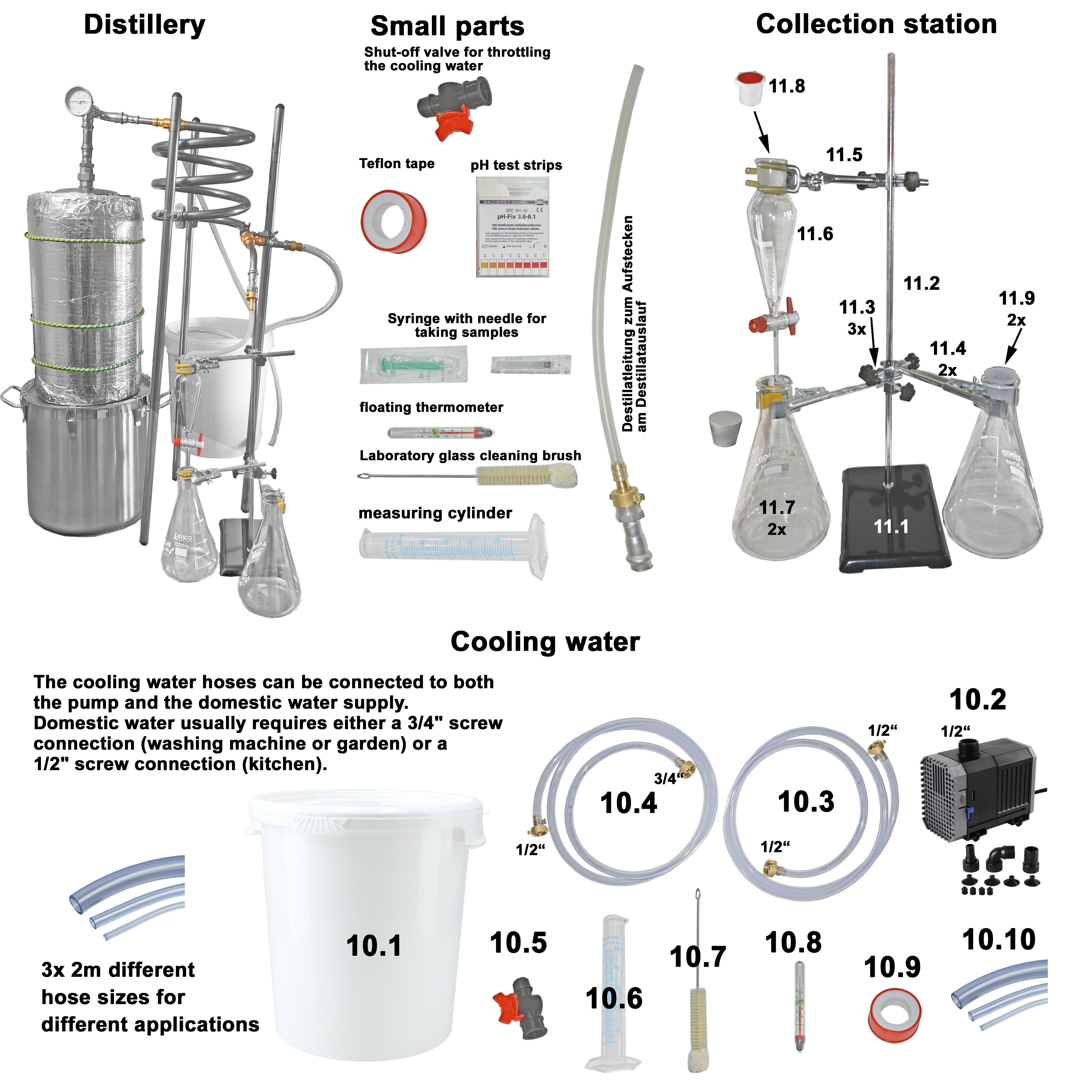

DESTILLIERMEISTER E25-12 Suprem deLúxe - all inclusive, with heat-insulated plant tube to prevent backflow losses

With everything you need for distilling and analyzing

For the distillation of essential oils with 25-liter water/steam boiler for multiple distillation runs

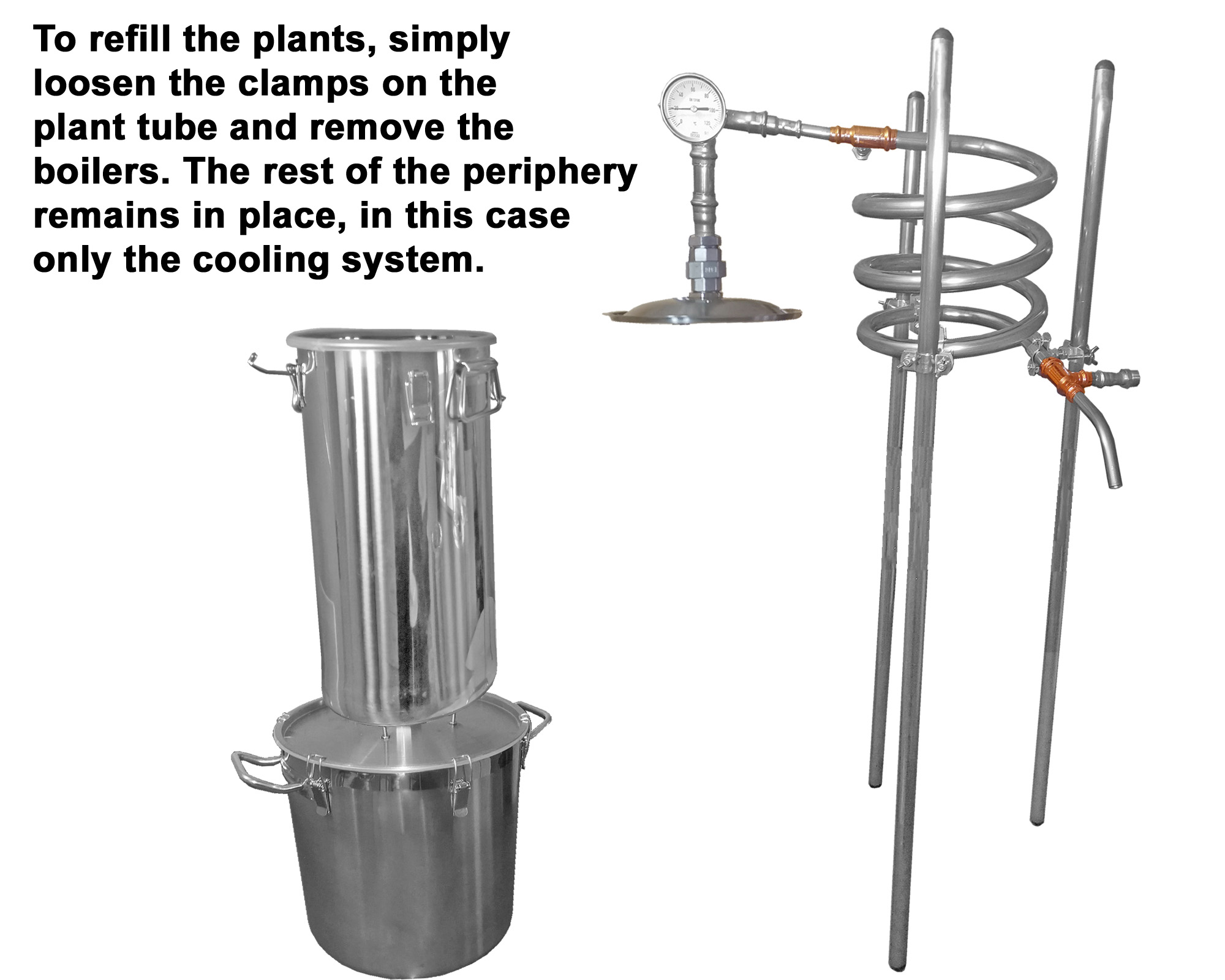

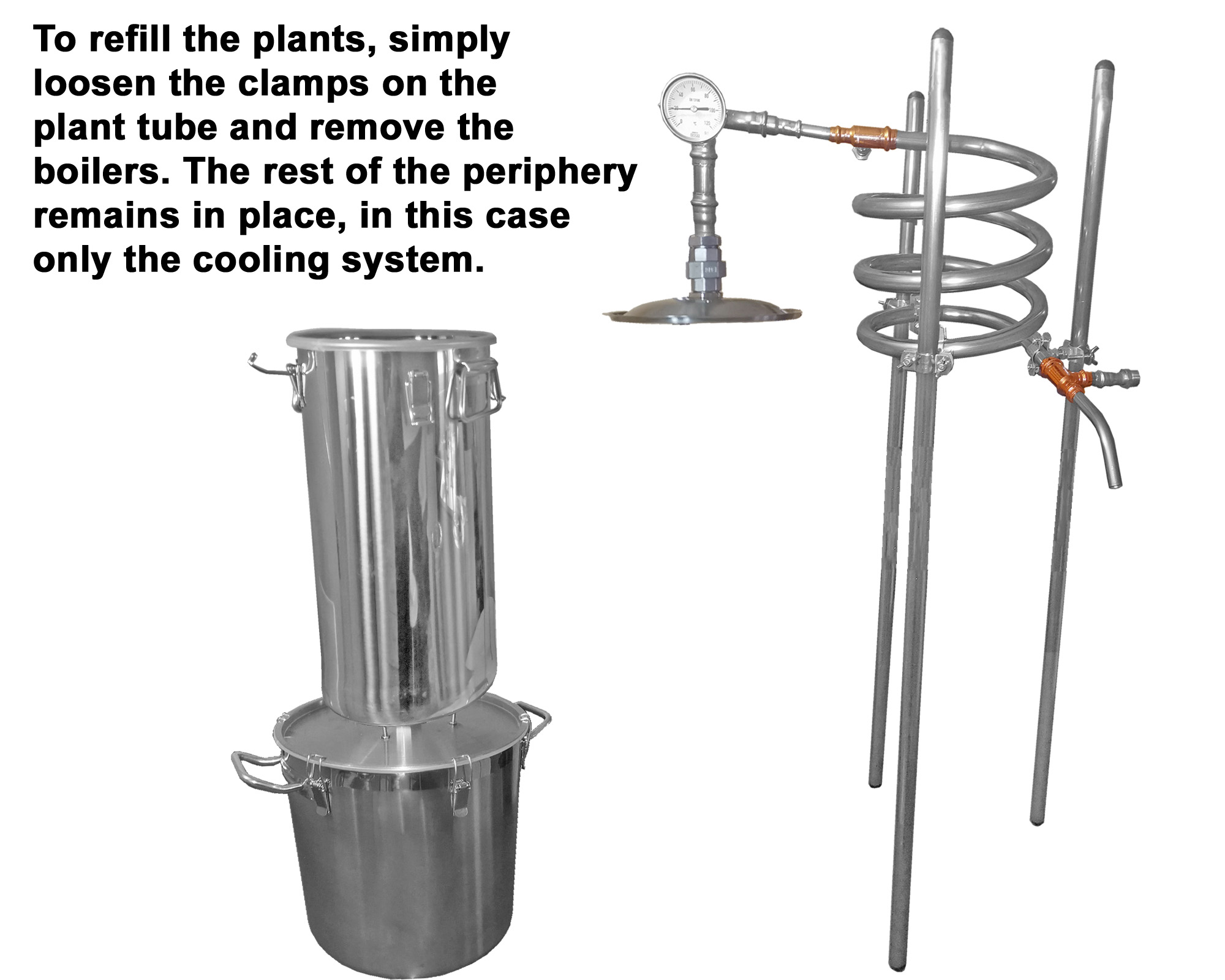

The DESTILLIERMEISTER E25-12 Suprem deLúxe has a self-contained distillation bridge for quick refilling and resealing.

With its 12-liter plant volume, larger quantities of plant material are required. The 40 cm height and 20 cm diameter create a decent chimney effect during distillation. The chimney effect promotes the entrainment of essential oils. The height-adjustable aroma basket also allows you to work with smaller quantities. If distilling with less than half the filling height (6 liters of plants), the heating power should be reduced. However, we recommend working with no less than 4 liters of plant volume (1/3 of the total height in the plant tube). There should be no empty space at the top of the plant tube, as this leads to higher oil losses.

For most plants and flowers, the water supply is sufficient for about 2 distillations when 2 liters of distillate are extracted per distillation. The use of a large boiler for hydrolate production is also completely legal in Germany. However, you must report a boiler larger than 2 liters to customs, but you can then use it without restriction as long as no alcohol is processed – even for private use.

With the appropriate permit – e.g., if you are working commercially – this system is also ideal for alcohol distillation. In these cases, the plant tube serves either as a column for mash distillation or as a container for fruits or herbs in alcohol vapor distillation.

With 12 liters of plant space, you have plenty of volume to process larger quantities of plants or drugs in one distillation. Since the steam is generated in a separate boiler under the plant container, there is no contact with boiling water. However, you should only fill the boiler with a maximum of 8.5 liters so that the steam can develop in the boiler and no hot water is drawn up if boiling is delayed.

When using the entire plant pipe, at least 3 kW should be available as a heat source, either induction or gas.

Easy handling for production:

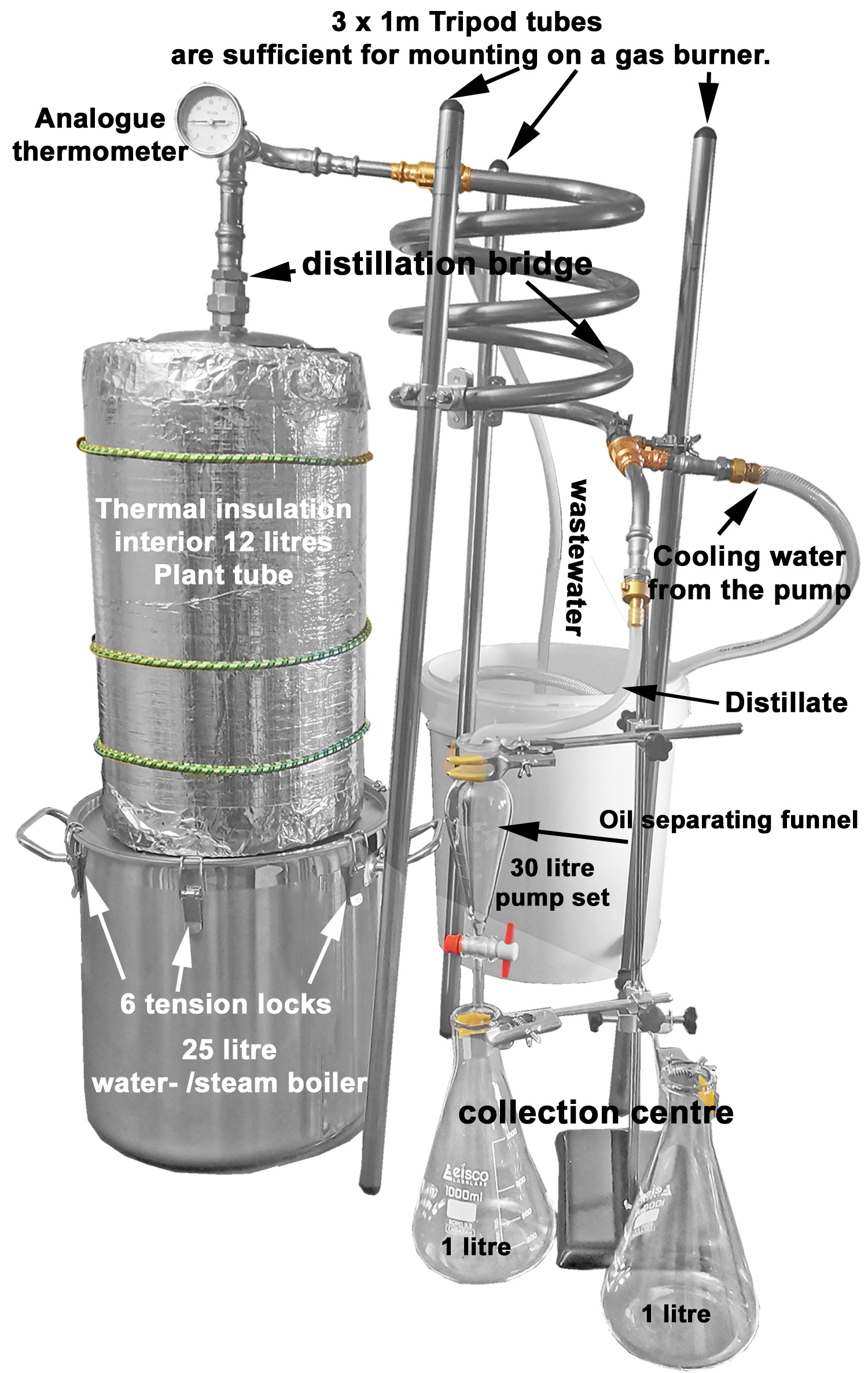

- Fill the water/steam boiler with a maximum of 23 liters of water, either demineralized or distilled water, or tap water if the limescale is removed from the bottom of the boiler after a few distillations using heated citric or acetic acid.

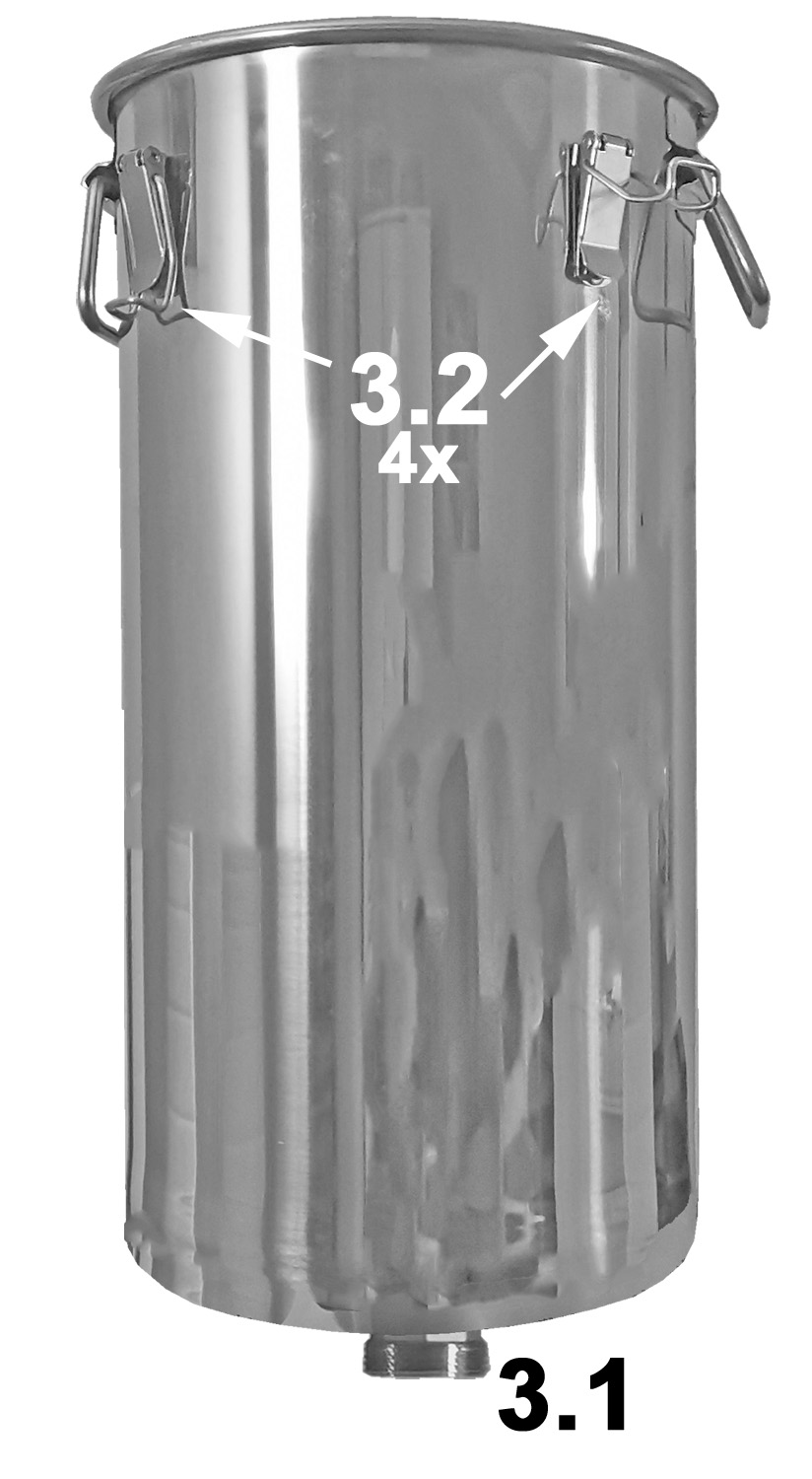

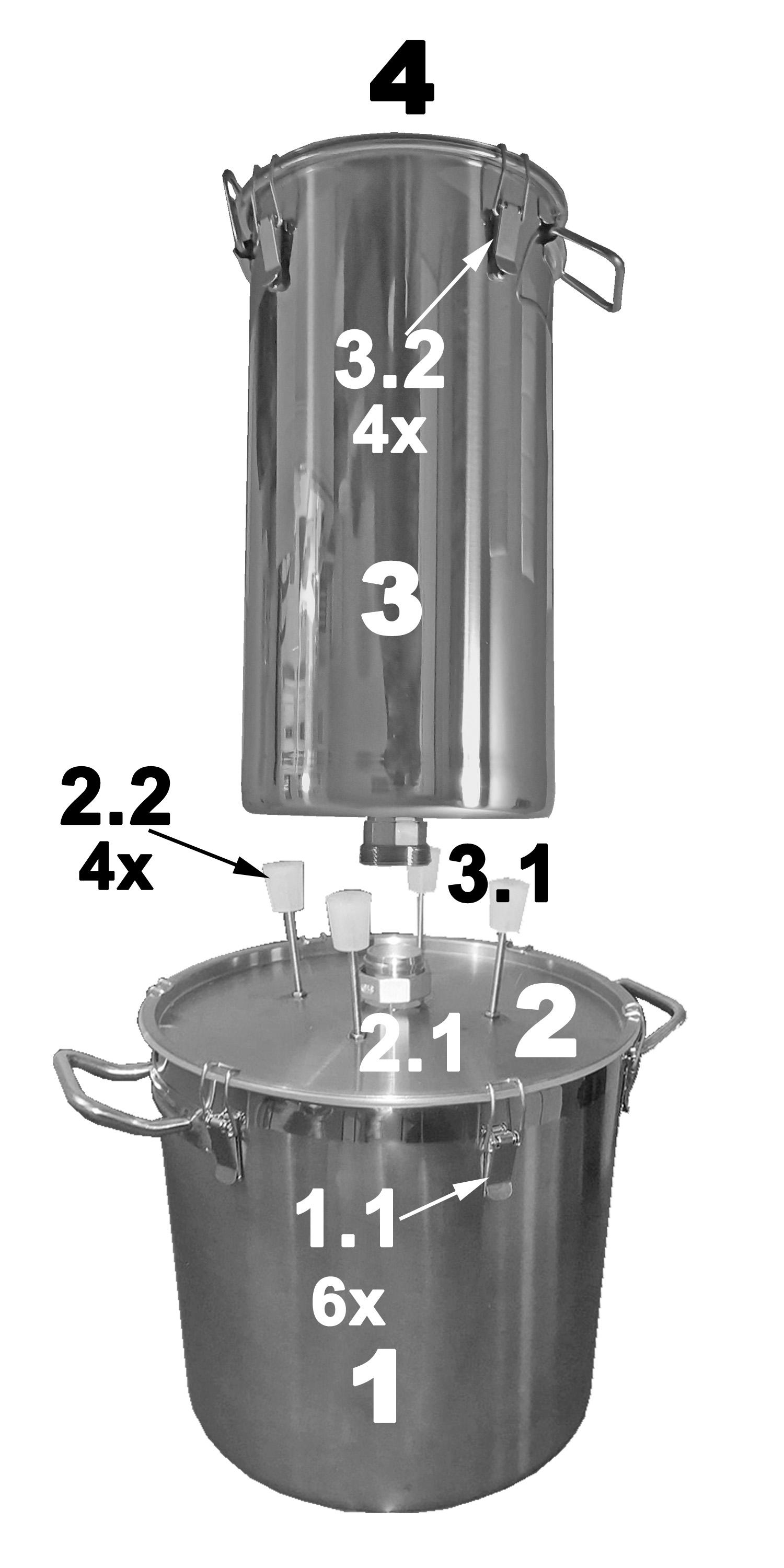

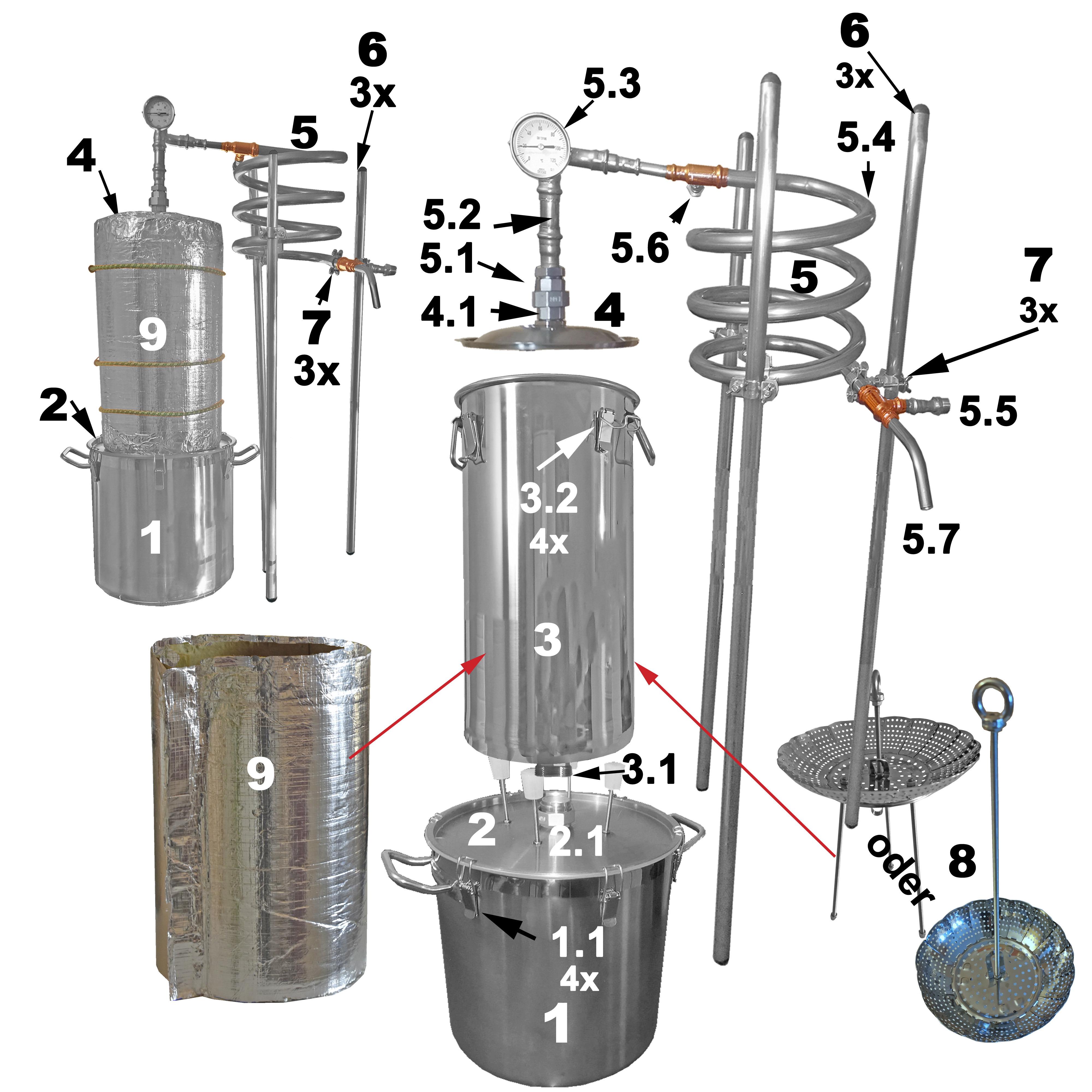

- Place the plant tube 3 with the lid 4 on top and close with the clamps.

- Insert the aroma basket 8 into the plant tube and open it. Now fill the plant tube, pressing down lightly. In this offer, the filling quantity of the plant tube can be reduced by placing the aroma basket at the top.

- Place the lid 4 with the 3/4" screw connection 4.1 on top and close with the clamps.

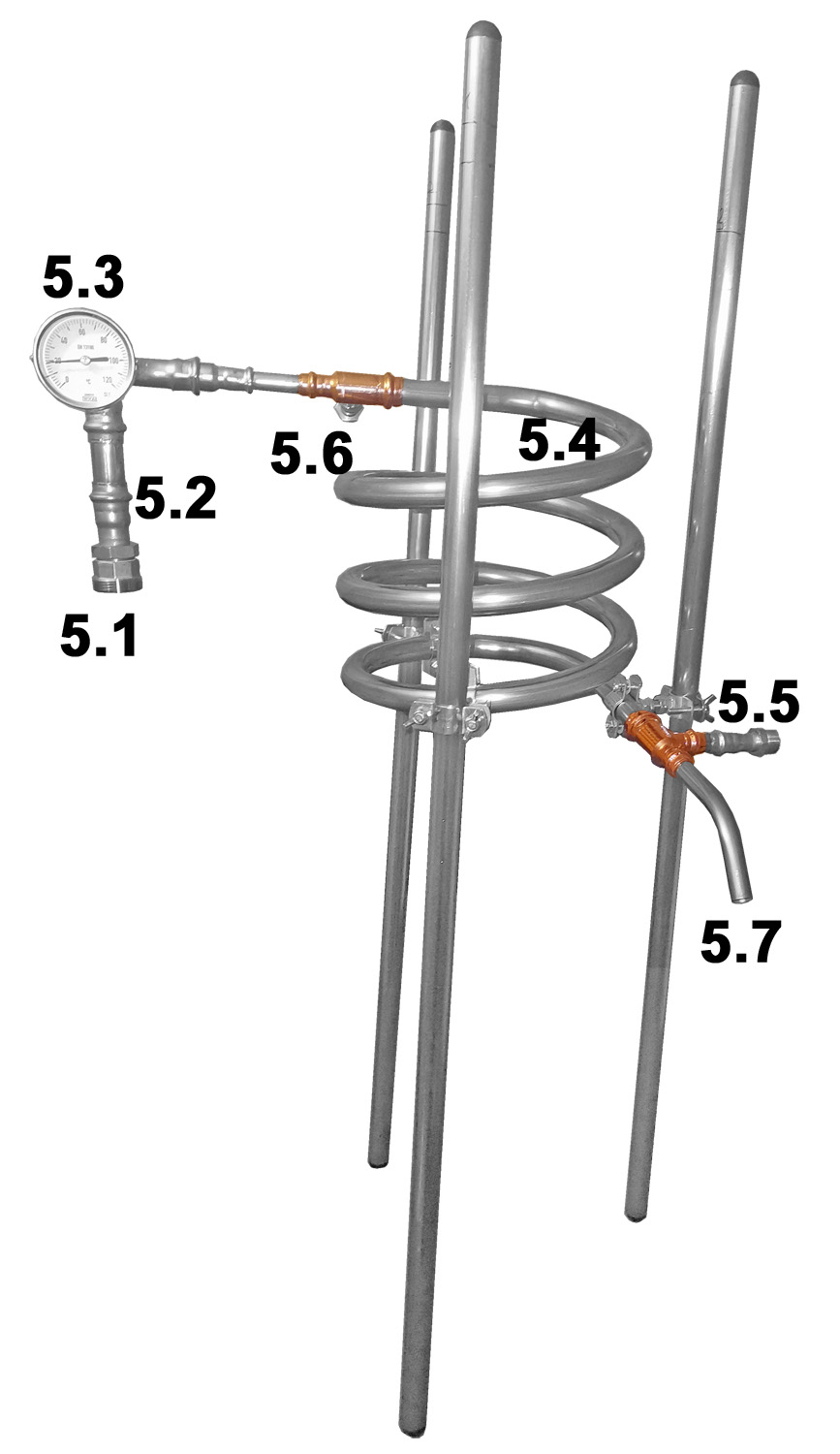

- Screw the riser pipe of the distillation bridge 5 onto the lid and tighten – the connection is metal-sealed.

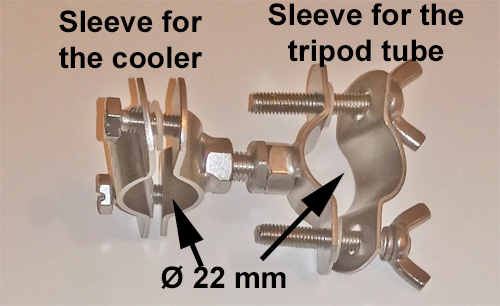

- Support the bridge 5 with the supplied stand tubes 6. and the cross sleeves 7. attached to the cooler (see below). The stand tubes are long enough to provide support even when using a higher heat source. The markings on the cooler and stand tubes are designed for a level setup. When using a raised heat source, simply move the mark up by the height of the heat source.

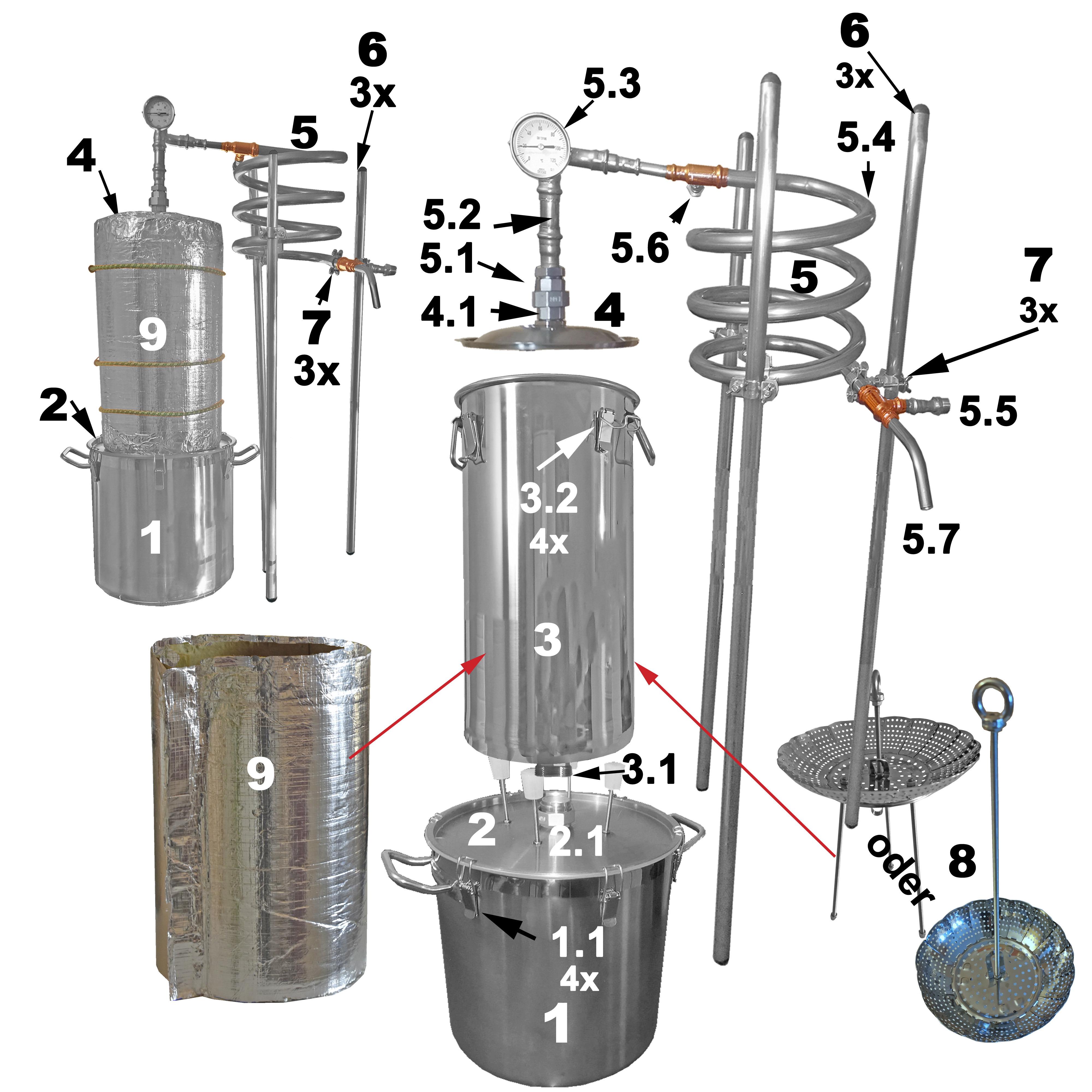

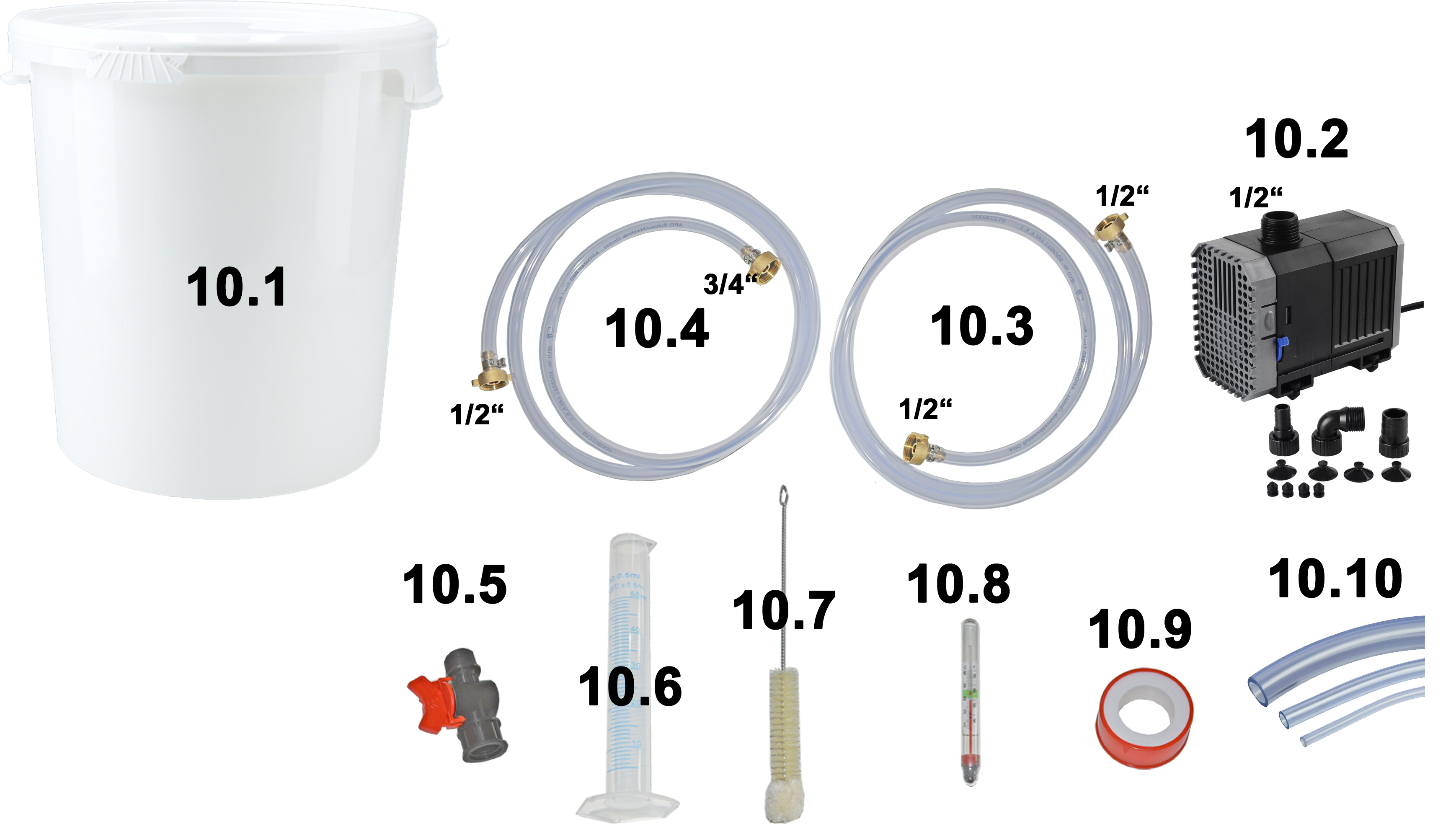

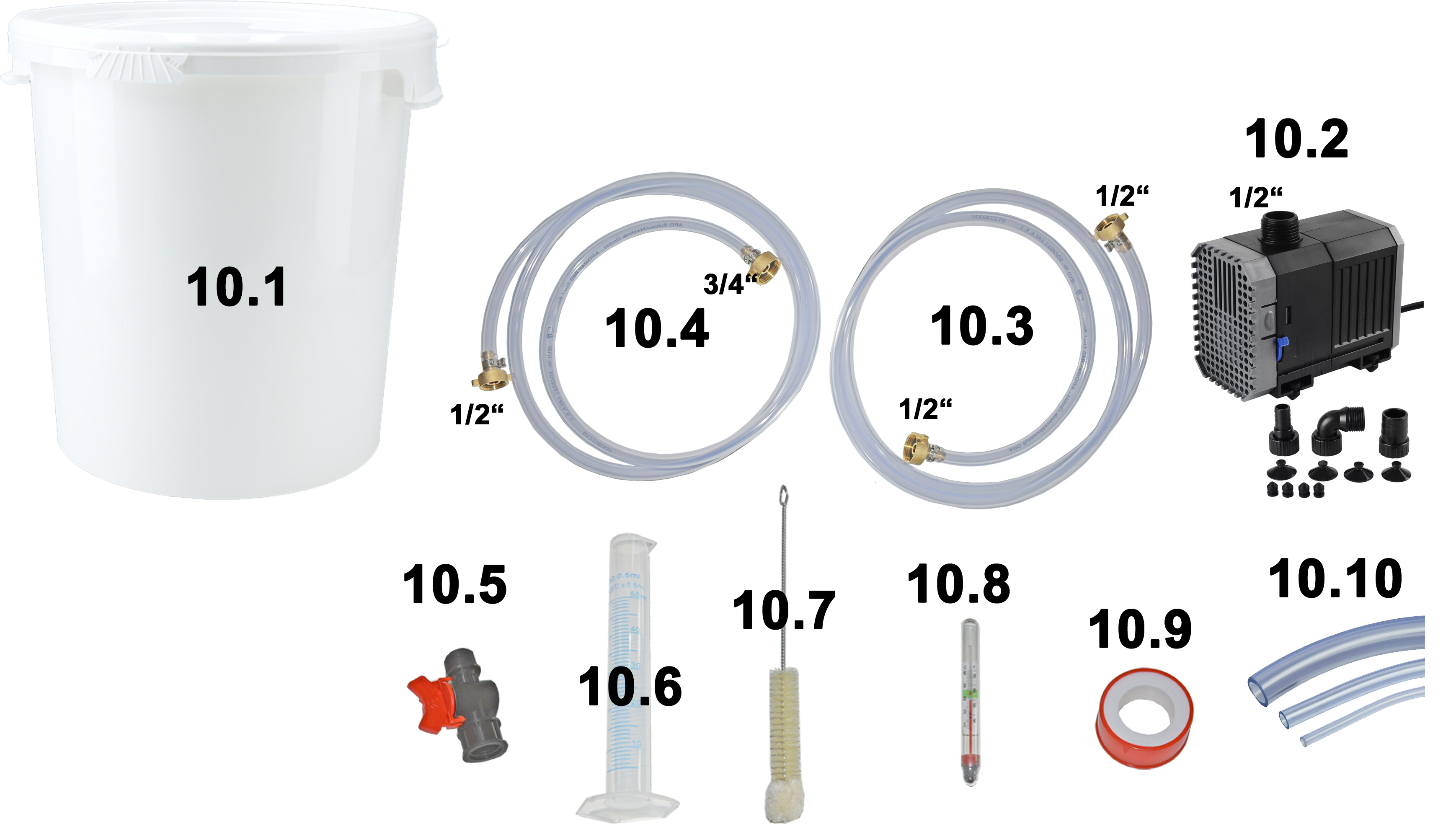

- Connect cooling water hoses 10.3 and 10.4. If you want to remain independent of tap water, you can use the pump set. The hoses supplied are prepared for both variants. In the example here, the waste water is returned to the 30-liter container.

- The water inlet starts at the cooler at 5.5. Here you need a 1/2“ hose screw connection on the hose. The cooling water then flows upwards between the pipe core and pipe jacket in the opposite direction to the distillate and exits at 5.6. Here, too, you need a 1/2” hose screw connection.

- Switch on the heat source and collect the hydrolate at 5.7.

- When the plant tube is full, 2 liters is sufficient for most plants and takes about 30 minutes at a minimum power of 3000 watts. A heat source with more power shortens the distillation time.

Since the plant tube has a large surface area due to its size, a lot of heat is lost through it. It therefore makes sense to insulate this surface, which prevents oil loss due to dripping back onto the cooler surface. For this purpose, we use aluminum-coated rock wool insulation rolls that can be easily wrapped around the plant tube. This is what it looks like:

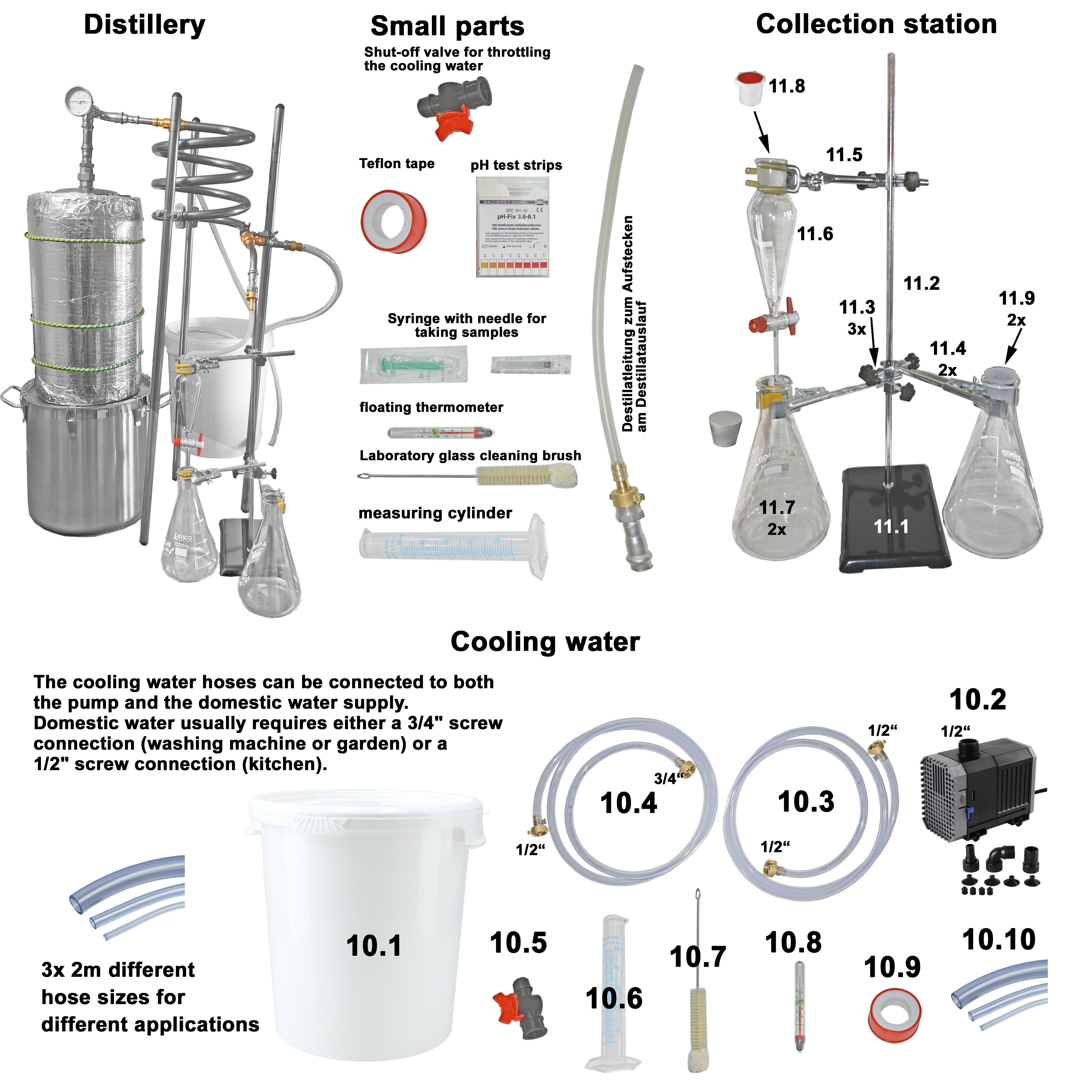

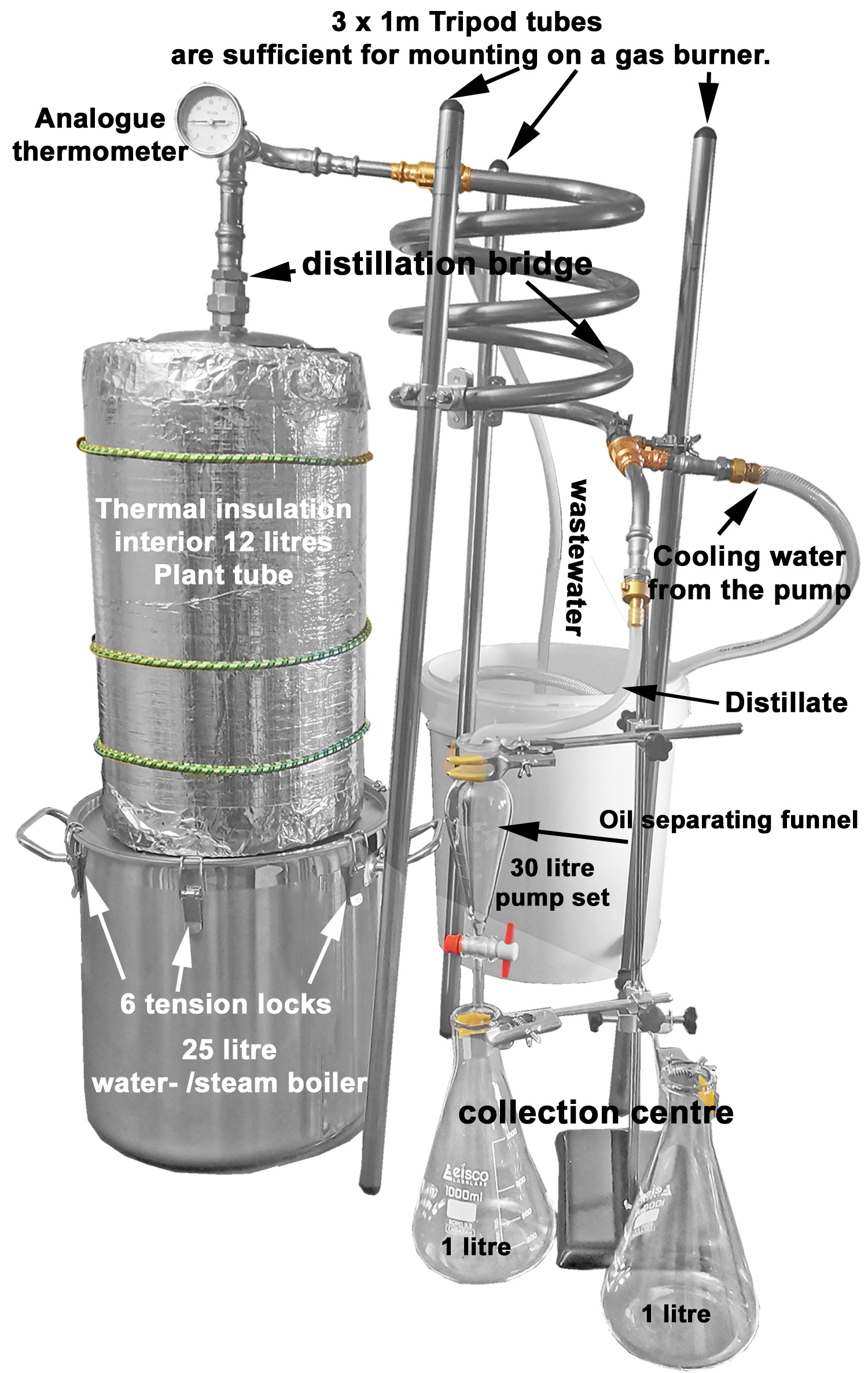

Setup with insulation in operation with cooling water supply and hydrolate collection station.

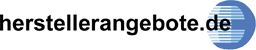

Scope of delivery

The distiller with insulation.

Details

- Water/steam boiler, 25 liters. Approximately 23 liters of water are filled in.

- 6 clamps for securely closing the water/steam boiler.

- Lid for the boiler

- 1“ stainless steel screw connection for the plant pipe; conical seal.

- 4 vibration damping supports.

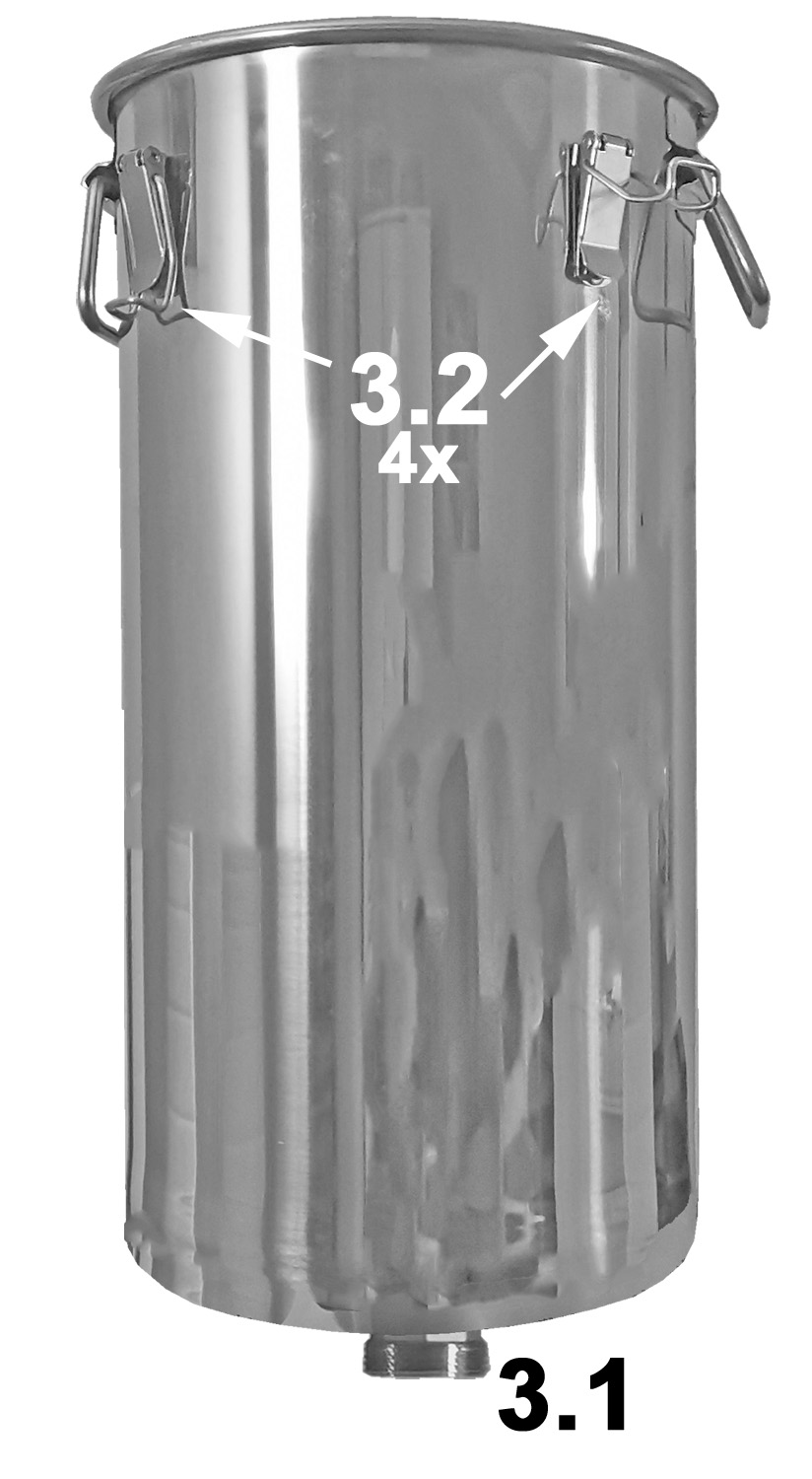

- Plant/drug pipe, approx. 12 liters capacity.

- 1” screw nipple for screwing to 2.1.

- 4 clamp fasteners for secure closure.

- Lid with screw connection for distillation bridge 4.

- 3/4“ V4A screw connection for distillation bridge.

- Distillation bridge with counterflow performance cooler spiral, with generous 2.5 m cooling length.

- 3/4” screw nipple, suitable for screw connection with 3.1.

- riser pipe

- Stainless steel analog thermometer 0-120 ºC, accuracy class 1 - easy to read.

- Double-pipe counterflow cooler (outer jacket, inner core. Cooling water flows between the core and the jacket, and steam or liquefied distillate flows in the core. Cooling water and distillate flow in opposite directions.)

- Cooling water inlet

- Hot water outlet

- Hydrolate outlet

- Tripod tubes 3 x 1 m long

- 3 cross sleeves for use with the tripod tube to support the distillation bridge.

- Aroma basket with long handle for insertion into the steam pipe or adjustable with short handle for processing smaller quantities. The handles are screwed into the central threaded hole from above and secured at the bottom with the wing screw. The legs are screwed into the prepared threaded holes from below to the desired length and hand-tightened with the nuts from below and above. For smaller quantities, the heating power may need to be reduced.

- Heat insulation for the plant pipe

- Pump set for working independently of the domestic water supply. However, if domestic water is available at the work site, hoses 12.3 and 12.4 can also be connected here, because hose 12.4 can be screwed onto a standard 3/4“ connection (e.g., washing machine connection or garden) or hose 2.3 can be screwed onto a 1/2” connection in the kitchen.

- 30-liter water bucket

- Powerful 20-watt water pump with a pumping height of up to 3 m. This allows the water supply to be located under a work table.

- 2 m hose for connecting to the pump and screw connection for the cooling water inlet at 4.5

- 2 m hose for the hot waste water to connect to 4.6.

- Shut-off valve for throttling the water flow if necessary.

- 50 ml plastic measuring cylinder for sampling.

- Cleaning brush.

- Floating thermometer; the cooling water temperature should be reduced from around 45 °C.

- Teflon tape in case of leaks.

- 3 x 2 m additional hose sizes for various applications.

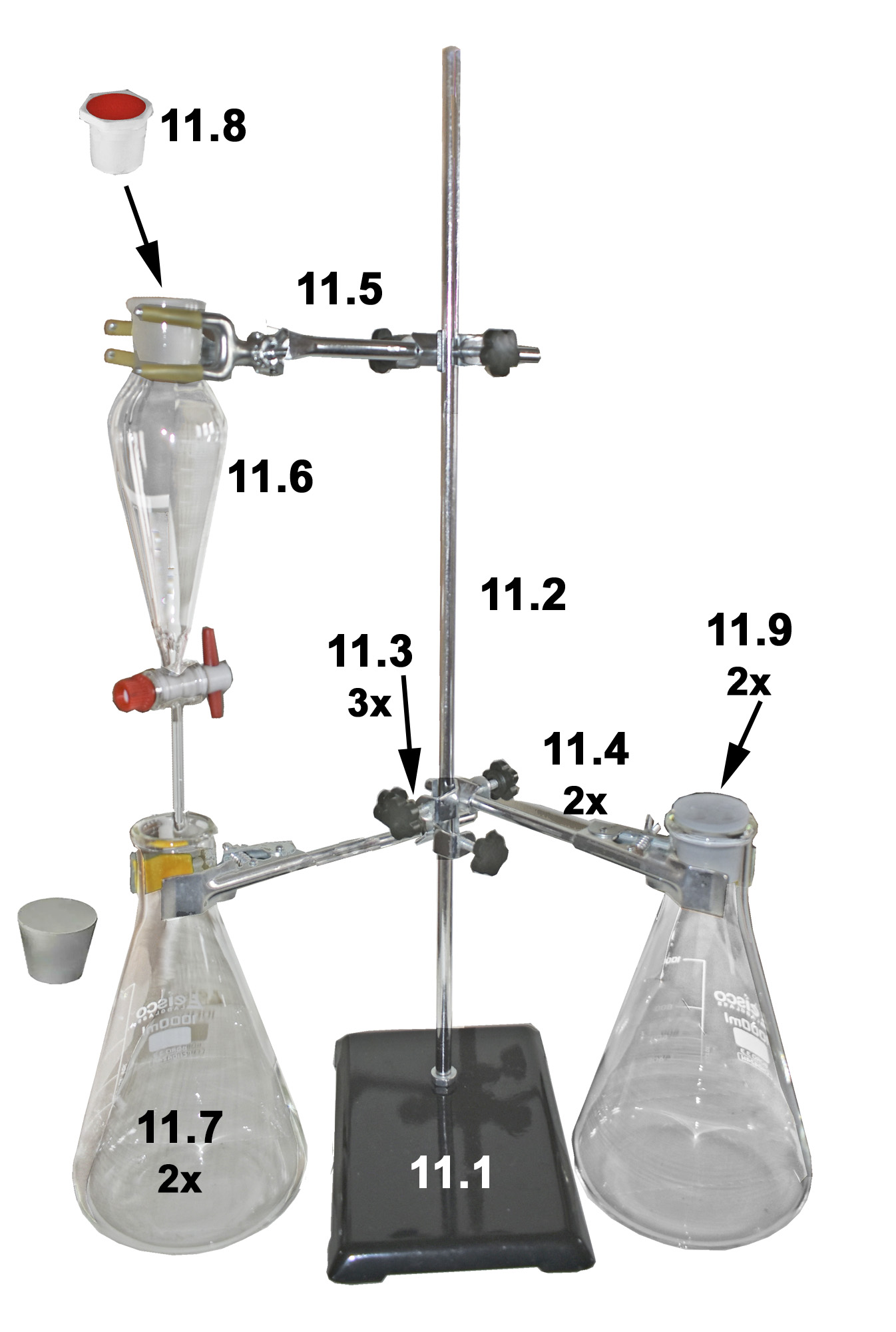

- Hydrolate collection station

- Base plate for the laboratory stand

- Stand rod

- 3 x cross sleeves

- 2 x laboratory clamps

- Laboratory clamp with tiltable gripping arm

- 100 ml separating funnel or oil separator

- 2 x 1000 ml Erlenmeyer flasks as collection vessels for the hydrolate

- Stopper for the separating funnel

- 2 rubber stoppers for the Erlenmeyer flasks.

- Distillate line with stainless steel plug. You can simply attach them to the distillate outlet 4.7 using the stainless steel socket. You can also use 14. to rinse the distillation bridge by unscrewing the distillate line. You can then connect one of the water hoses to the thread.

- pH measuring sticks, pH value between 3.6 and 6.1, 100 pieces. A hydrosol with a pH below 4 is of very high quality. At a pH of 6 or above, you should decide whether you want to stop the distillation. The hydrosol still smells good, but is no longer as suitable for storage.

Test with the 4-liter plant pipe

Heat source: Induction, power 3000 watts.

Drug: Dried lavender flowers

Quantity: 400 g

Total distillation time: 14–16 min

Hydrolate extraction:

500 ml after 8 min, oil yield approx. 25 ml, hydrolate pH value: 3.2

The quantities may vary depending on the harvest or harvest time. Rain shortly before harvesting can significantly reduce the yield. Harvesting should take place after at least 2 days of sunshine. Either distill fresh or dry gently for later distillation.

GPSR information and manufacturer's instructions